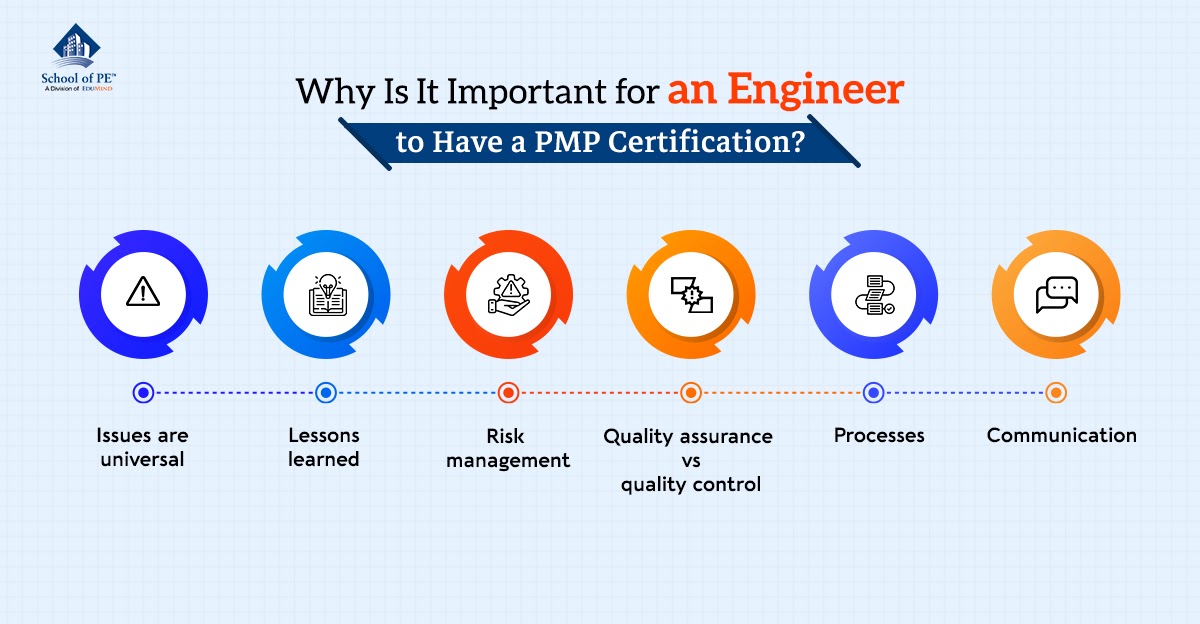

This article goes beyond any monetary rewards that a person will obtain with the certificate itself and will focus on the tools that engineers will learn when preparing for the PMP exam

1. ISSUES ARE UNIVERSAL

Ask any engineer: do your projects run smoothly all the time? Or how about... never? Projects always have roadblocks. The PMBOK (Project Management Book of Knowledge) calls these events issues. There are many types of issues but let us think specifically about events that affect our schedule, our cost, our quality, or even our reputation.

Should we avoid having any issues? Maybe, but a project without issues is unrealistic. What you want to avoid is repeating issues ("fool me once, shame on you, fool me twice, shame on me"!) Have you ever had the same type of issue more than once? How about the same issue, but in other projects? The PMBOK introduces the concept of an ISSUE LOG, which is a place where issues are recorded. This is one of the sacred rules of project management: registering; leaving a trace. This way it is easy for a person to register issues, and another person or team can be assigned to resolve them. So, the first practice is to acknowledge that issues are common in projects, and that projects shall always have an ISSUE LOG to keep track of open and closed issues, and most importantly, a place where these events are stored so that people in organizations can LEARN from them.

2. LESSONS LEARNED

Projects have many phases: initiation, planning, execution, control, and close. Issues may occur in any of these phases. The most important part of transitioning one phase to the next is the LESSONS LEARNED. It is not very savvy to wait until the end of a project to discuss what was learned in each phase. Think about a construction project: engineers may work on design, and then leave the installation portion to other parties or other companies. More so, even if a project engineer oversees a project from beginning to end, a project may take years to finish. So, between phases, there should always be a GATE CHECK. In a gate check, it is good practice to go over the issue log and discuss how issues were resolved. In many cases, there will be resolutions of issues that made a process better and the team wants to make sure that the new process is done from now on in new projects. These is when these new practices are added into the BEST-KNOWN WAY REPOSITORY. This is an exceptionally good method to learn from our mistakes.

3. RISK MANAGEMENT

How do we approach new projects or new phases? If we have good issue management, then issues that have been identified in previous projects automatically become RISKS on new projects. These types of risks are called risks from historical performance or historical data ("I will not let that issue happen again on my watch!). Of course, you can identify risks without having gone through an issue once before. This is when expert insight, or expert judgement is so important: we need subject matter experts to help us understand where any project can go wrong.

The way we record risks is on a RISK REGISTER. To assess risks, the expert or the data should help us understand how likely the event is to occur, and if it does, how damaging it can be to the project cost, the schedule, or the quality of the project. Identifying risks is not easy, but it does become easier if engineers practice recording issues and lessons learned meetings. Once risks have been identified, the next is to think of risk controls: we can mitigate risks (which basically means to have an action plan), transfer risks (i.e. hire someone), avoid risks (i.e., if your risk is related to winter problems, then work during summer!), and accept risks (this is when it is deemed that taking any action is more costly than letting the risk become an actual issue in the project). Lastly, there should always be a risk owner that is able to execute the controls.

4. QUALITY ASSURANCE VS QUALITY CONTROL

The PMP is highly effective in reminding us that we should always have a quality control plan, for all phases of our projects. We might be incredibly good engineers; some of us have a strong stance that everything we produce is of high quality. But let us think about quality control when a third party performs it: if you participate in doing a task, then someone else comes and reviews it, and a quality control plan will provide the parameters to compare. For example, engineers might be familiar with the 15%, 30%, 60%, 90%, and 100% milestones that are typical of design phases and design submittals. A quality control plan will explain what is expected to be produced in each phase, and what the quality control person is expected to check and compare against scope and against quality control standards of the company.

Another concept very frequently missed is Quality Assurance. This is not related to artifacts or deliverables, rather than to the processes. An effective way to make sure processes are being maintained is by performing QUALITY AUDITS. These are typically done unannounced: an auditor will make sure that at a certain point of a project the processes have been respected. This applies to everything: even things as banal as project folder structures: does your folder in one project look different from the project folder structure of another? You might want to revisit the processes in your organization. Standardization is important in successful companies, and you may want to be a pioneer in setting quality audits to make sure your business unit is aligned with quality objectives of your enterprise!

5. PROCESSES

If you think about everything as a process, then you will be able to find ways to improve them. The most important think about any process is FEEDBACK, because this is when outputs are verified, and how processes just keep getting better.

No comments :

Post a Comment